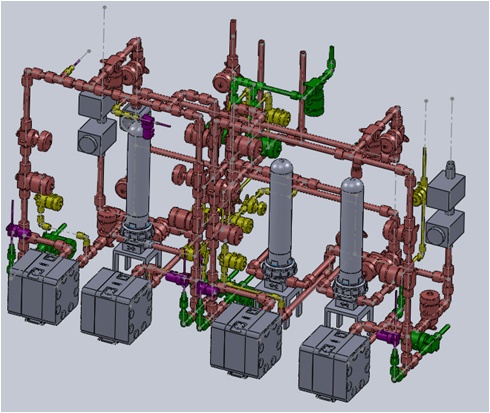

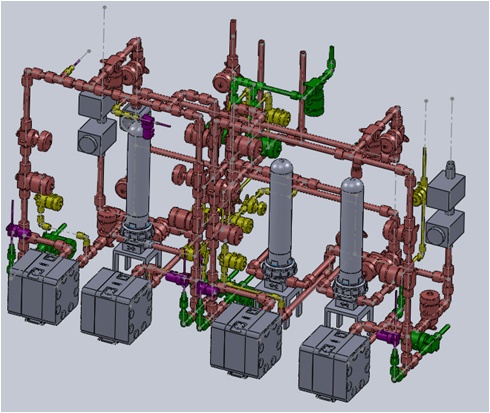

Main Features of Acid / Caustic Modules

Main Features of Acid / Caustic Modules

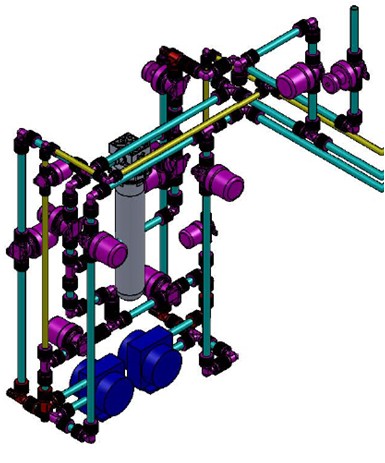

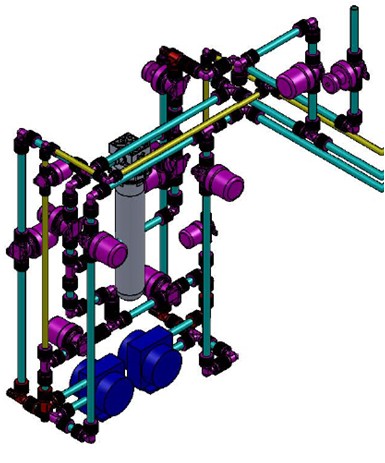

Main Features of Solvent Modules

TECHNICAL DATA

TECHNICAL DATA

OPTIONS

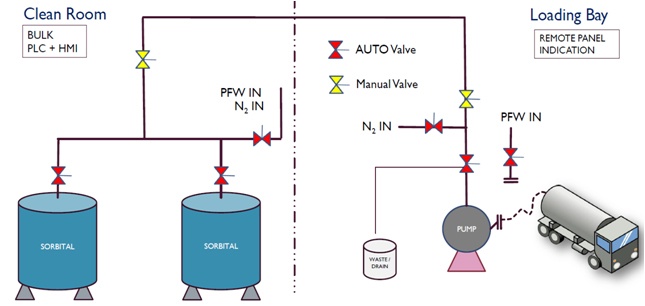

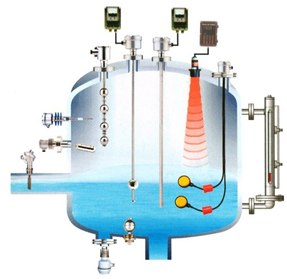

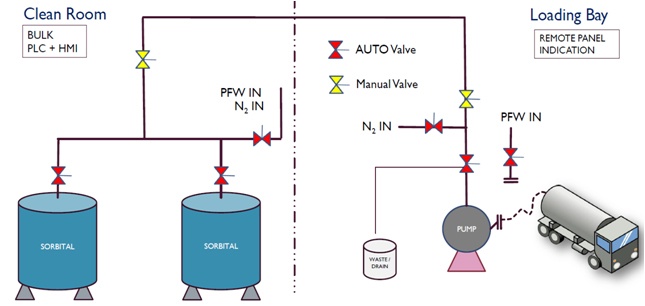

Tank blanketing, is the process of applying a gas to the empty space in a storage container. The term storage container here refers to any container that is used to store products, regardless of its size. Though tank blanketing is used for a variety of reasons, it typically involves using a buffer gas to protect products inside the storage container. A few of the benefits of blanketing include a longer life of the product in the container, reduced hazards, and longer equipment life cycles.

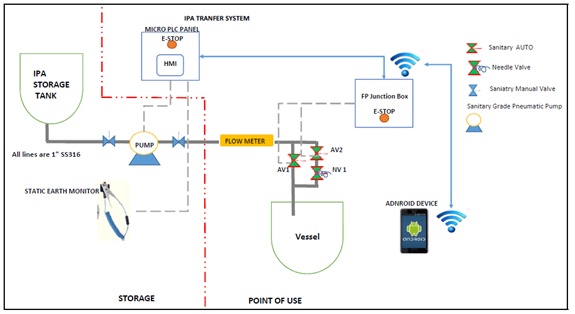

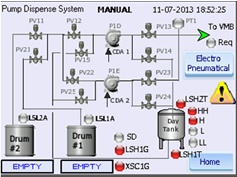

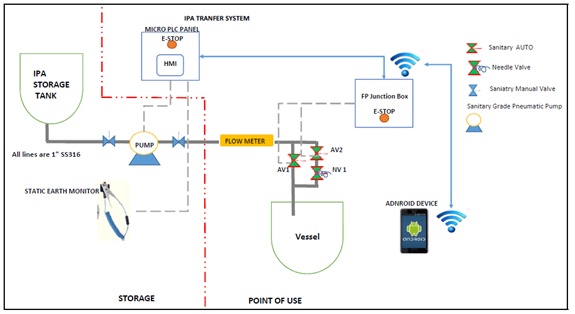

The SCADA System Operates with coded signals over the communication channels to provide the clients to monitor & control the remotely operated systems. By combining the Data Acquisition, the users acquire the information such as status of the equipment, Alarms from the Field instruments, Recording of data for trending…etc.

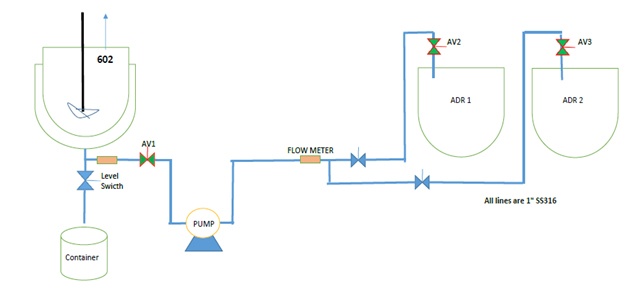

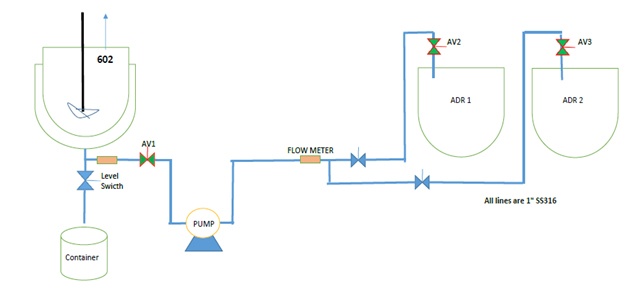

In Continuous Level Measurement, the level of the medium in a tank is detected & converted into an electrical signal. The signal is incorporated in the controllers or displayed locally. From the controllers, the signal in terms of % level is transmitted to the monitoring station, Alarm Monitoring system through the networking. This enables the user to have a remote monitoring & controlling.

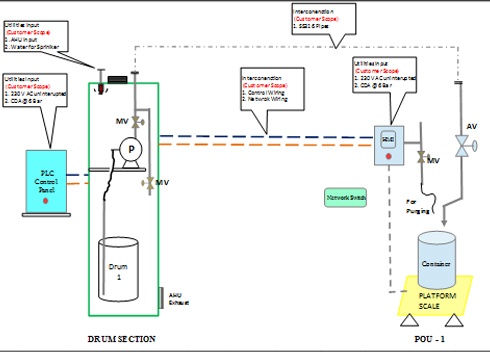

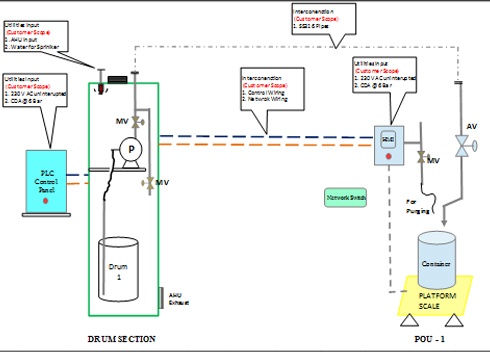

Solvent Dispensing Modules are custom designed and fully automated solution widely used in Pharmaceutical, Food & Semi-conductor industries for continuous supply of solvents to POU(Point of Use) in a safe and smooth manner.

SDM helps in reducing manual intervention of solvent handling resulting in safe dispensing and increased productivity.

We have Partnered & executed structural and piping projects in Pharma industries & other major Automobile industries.